OVERVIEW

Air Conditioning & AC Services

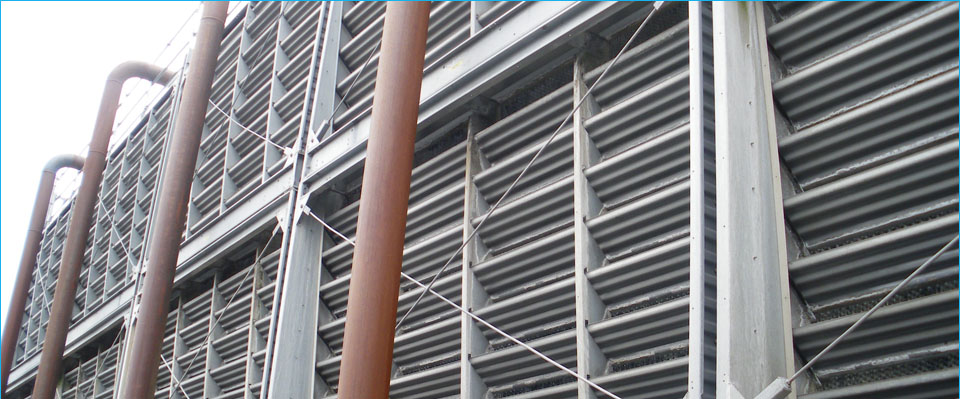

Only BoilerTreatment.com offers our high quality specialized water treatment chemicals and services for boilers and cooling tower maintenance, boiler treatment, air conditioning and chilling towers and systems treatments, systems restoration.

OVERVIEW

Causes Of Cooling Problem

Power, process, and refrigeration systems all develop a sizable byproduct heat. Whether generated from a centrifugal or reciprocating refrigeration machine or an absorption machine, heat needs to be dissipated. Typically, this is accomplished by recirculating water through a cooling tower. Scale deposition, corrosion, micro biological growth, and fouling can cause problems in the cooling system’s heat exchangers, water-carrying lines, and other system components.

If cooling water is left untreated, a point is reached where the water can no longer maintain the impurities in solution. This is called the level of saturation. The level of saturation depends upon temperature, concentration, and level of pH.

Scale deposits interfere with heat exchangers and reduce their efficiency by insulating the heat transfer surfaces. The most common form of scale in cooling water systems is calcium carbonate (CaC03). In the water, calcium ions combine with bicarbonate to form calcium bicarbonate: (Ca++)+(2HCO) Ca(HCO3)2.

As the temperature of the system increases, calcium bicarbonate is converted to calcium carbonate in the following manner: Ca(HCO3)2+heat> CaC03+H20+CO2.

If scale deposits are left to accumulate, water flow is restricted and piping and heat exchanger tubes become plugged. Ultimately, ignoring scale depositions can lead to the destruction and possible failure of heat exchanger tubes. In addition to loss of efficiency, process contamination can occur.

Cooling systems are continuously infected with microorganisms. If not controlled, micro biological populations multiply rapidly in the warm cooling-water environment. The accumulation of micro biological growths can lead to fouled heat exchangers, metal deterioration through corrosion, and clogged filters and screens.

Fouling results from the physical accumulation of suspended solids on heat exchanger surfaces. Suspended solids include micro biological growths or byproducts, organic material, and precipitated inorganic matter.

OVERVIEW

Cooling Problem Solution

If a cooling water system is to operate effectively and efficiently, treatment must be used to address the problems of scale, corrosion, micro biological growth, and fouling. These problems can be addressed either with internal chemical treatment or with the use of external pretreatment equipment, such as pressure depth filters and centrifugal separators. The success of a water treatment program for cooling towers depends on the proper selection and application of chemical products and equipment, as well as following established bleed-off procedures.